A turbofan engine is a type of gas turbine engine used predominantly by medium to large aircraft. If you have ever seen a commercial airliner before, chances are that you’ve seen a High-Bypass Turbofan Engine (we will go into bypass ratio later in this article).

Turbofan engines generally deliver a better thrust to weight ratio than similarly sized reciprocating engines (like those used in cars), that is why you won’t see a large airliner with a reciprocating engine because the weight the engine with relation to the thrust produced is far less efficient than that of turbofan engines. The other reason for the use of Turbofan engines are because they are far more reliable than their reciprocating engine counterparts. All the components in a Turbofan move in the same direction unlike a reciprocating engine.

The Principles behind Turbofan engines.

The primary scientific principles being used in the turbofan engine is Newtons 1st law of motion.

“A mass at rest or constant velocity will remain at rest or constant velocity until acted upon by an external force, when acted upon by a force the mass will accelerate in the direction of the force”

The mathematical expression for Newton’s 1st law is

The principle is: Air coming into the engine is accelerated through the engine and then exhausted out, the accelerated air in the engine is used to drive the fan which in principle is the same as a propeller but with far more blades. The combination of the driven fan and accelerated exhaust gases cause a forward thrust, this thrust is what gives the airplane its forward motion.

Stage of Turbofan engines

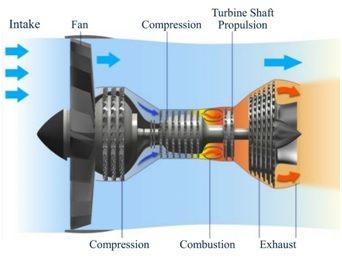

There are four main stages in a turbofan engine; Intake; Compression; Combustion; and Exhaust. Each of these four stages work together to ultimate produce thrust.

Each of these four stages work together to ultimate produce thrust.

Intake Stage

The intake stage of the turbofan engine feeds the compressor of the engine with cold air. Some air flows through inlets of the engine and some air flows around the outside of the engine, this air is said to be bypassed, because it doesn’t go into the engine. The ratio of the inlet air and the bypassed air is usually referred to as bypass ratio.

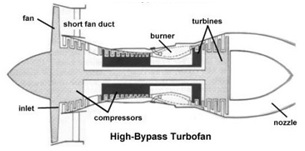

Most large airline Turbofan engines are High-bypass Turbofans, which means the mass flow rate of air that flows over the engine is significantly more than that which flows into the jet engine.

High-bypass Ratio

The two significant advantages of High-bypass ratios are lower fuel consumption and lower noise production. These two advantages are the reason why airline executives choose to purchase High-bypass engines in larger numbers than the less efficient low bypass engines.

Image from: The Worlds of David Darling

[As shown in the diagram, a large mass of air flows around the core]

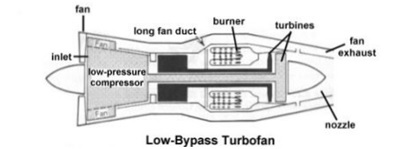

Low-bypass Ratio

The main disadvantage of high bypass ratios is that they are limited to fly at subsonic speeds (slower than the speed of sound).

Image from: The Worlds of David Darling

[As shown in the diagram, less air flows around the core]

Compression Stage

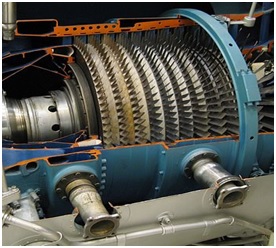

The compression stage of the engine is crucial to the efficient operation of any type of gas turbine engine. The compression stage ensures that the air is at the correct pressure and temperature to be ignited in the combustion stage. The compressor consists of stationary blades (known as stator blades) and driven blades (known as rotor blades), the combination of the rotating and stationary blades result in the air becoming highly pressurized and having higher thermal energy.

The hot pressurized air then flows into the combustion chamber.

Combustion Stage

The combustion stage along with the components in its chamber are responsible for the creating and burning the air-fuel mixture. The combustion chamber consists of a fuel injector system to allow fuel to be ignited and subsequently burned by the high temperature and pressure air. As the air fuel mixture burns it rapidly expands (increases in volume) and is forced out of the back into the exhaust stage. The immense energy of the expanding gases is transferred into rotation energy by means of a coaxial shaft connected to the post combustion turbine.

Exhaust Stage

The way the exhaust stage produces thrust is a clear manifestation of Newtons 3rd law.

“For every force there is a reaction force of equal magnitude and opposite direction.”

Mathematical expression: F1 = -F2 and force is equal to

The exhaust gases exit at high velocity out of the rear of the engine, the reaction force of the exhaust gases is in the opposite direction of the exhaust thus it is called thrust.

Turbofan Engine mechanics

The large fan is driven by this energy exchange and behaves like a propeller in the case of high bypass Turbofan engines. The expanding gases in the post combustion turbine stage drive the shaft that consequently drives the large fans. The large fan draws air into the bypass and compression chamber, which results in the air being at the correct pressure and temperature to ignited and combusted with the fuel.

But if the turbofan engine requires hot compressed air to combust the air fuel mixture, and if we need to drive the post combustion turbines to drive the fans which drive the compression stage, you may be asking. How does a turbofan engine start?

How does a Turbofan engine start?

The blades of the fan require rotational energy to start the combustion cycle, so engineers have designed a high-pressure inlet called an Air Turbine Starter. The air turbine starter is attached to the side of the engine

The air turbine starter is a small pressurized turbine that is driven by a start cart shown below. The start cart delivers pressurized air to the air turbine starter which is connected to the engine shaft through a clutch. Consequently, spinning the air turbine starter spins the engine compressor, which in turn compresses the air drawn into the engine. The air turbine starter continues to spin the shaft until the engine can idle independently of it.

Start Chart

Air Turbine Starter

Conclusion

Engineers and technicians are always finding new ways to improve the Turbofan engines of the 21st century. Now that you have an introductory understanding and insight into how a Turbofan engine works, try explaining it to a peer or family member. If they can understand your explanation, then you official know the basics of the turbofan engine. If not do yourself a favour and reread this article.