But recycling old and already existing aircrafts doesn’t often come up. Making new planes that will also be easier to dismantle isn’t something we hear a lot about either. We are going to discuss why recycling old airplanes is something we should be concerned about, and what is currently done to solve this issue.

First, we have to consider that this is a huge challenge. In 2014, there were more than 23,800 airplanes in service all around the world. These planes have a limited lifespan, of about 20 years, due to mechanical stress and certifications. This number is predicted to expand in the next decades to come. So what happens to these aircrafts once they are too old to fly?

At the moment, there are mostly two ways an airplanes’ life is ended: either in a storage space, or in a dismantling area.

One of the biggest storage areas in the world is the “309th Aerospace Maintenance and Regeneration group” containing about 4000 planes, but most of them are military airplanes. They are stored there for one of three reasons: too old to fly (and most of the time cannibalized for spare parts), waiting for a future buyer, or just kept in airworthiness conditions in case of a sudden need to reinforce the current air forces.

An aerial view of the 309th Aerospace Maintenance and Regeneration group in the USA.

Like this one, other graveyards are located most of the time in deserts, because planes are kept in better conditions in those locations, as it rarely rains for example.

As mentioned, this base is a military base, but lots of the planes flying are not only military, but also commercial, and private. The biggest civilian airplane graveyard outside of the US is located in Alice Springs, in Australia.

A part of the huge commercial airplane graveyard in Alice Springs, Australia

These solutions are good, but they are limited. Stocking old airplanes in huge graveyards isn’t really a solution, especially not one applicable on a large scale, because it’s just stacking airplanes, and not really doing anything else with them. So some companies have tried to come up with other solutions.

In France, there is a company called Tarmac Aerosave which is specialized in recycling (but also stocking) retired aircraft, located in Tarbes. It is the biggest European stocking company. The aim of this company is to dismantle an airplane to around 85 to 95% of its total mass, compared to 30 to 40% for other companies. Since 2013, they own 350 acres of stocking area (which represents around 250 airplanes) in Spain, in Teruel.

An aerial view of the Tarmac Aerosave headquarters, in Tarbes, France.

Two years ago, they had dismantled more than 50 airplanes at 90% of their mass. Usually, it takes around three weeks to dismantle one single airplane (though this depends on the size of the plane of course). This process is composed of three parts: depollution, disassembly and deconstruction.

- Depollution consists of taking away all and any kinds of fluid that are present in the aircrafts, in all the types of pipes and tanks. Pressurized water and/or air is send through the pipes to get rid of fluids.

- Disassembly is when the landing gear, engines, seats, and basically any equipment that can be sold again are taken apart. They are monitored, recertified, and sold back to other companies. In total, in average this represents around 13.5 tons of equipment that are taken from the airplane. This is also where most of the money comes from, since the engines are the parts that are the most valuable on old airplanes. They can be sold for more than $1 million each, which represents a lot for retired machines.

- Finally, once the different metals and materials locations on the airplane are mapped, the wings and fuselage are dismantled using special equipment, to be able to easily handle each part independently. Then, depending on the current rate of each metal, more or less rough (and thus costly) techniques are used to separate the different metals, and sell them.

There is up to 15% of the original mass that is hard to recycle (interior coating, luggage compartment, etc.). They are usually burnt because at the moment there isn’t any other real alternative.

While solutions like Tarmac Aerosave are good ones, they are nowhere near enough to answer the growing need that is coming of recycling retired airplanes. According to their own estimations, 6,000 civilian airplanes are going to be on the market in the next 20 years, which means 300 new planes per year, and this is only counting ones with over 100 seats. Tarmac Aerosave, as we mentioned previously, needs two to three weeks to dismantle an airplane, depending on its size, and only two to three airplanes can be dismantled simultaneously. This is why more and bigger companies and infrastructures are going to be needed in the very near future to be able to handle such amount of machines.

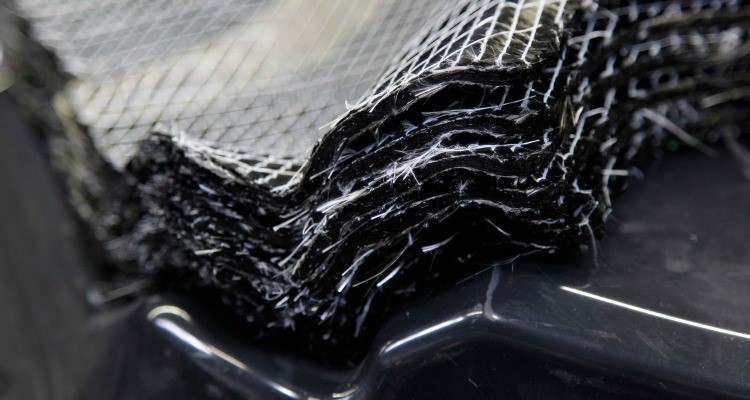

There are other problems we haven’t mentioned yet, like the fact that military and civilian aircrafts are totally different, not only on how they operate, but also on their equipment. Military aircrafts have very sensitive and most of the time relatively secret technologies onboard. How to handle the dismantling of these airplanes is something that cannot be done by everybody, and that has to be done in other conditions than the ones used for civilian machines. If recycling military aircrafts is even possible is in itself a question, because of sensitive technology. One other problem, that we are going to have to deal with, is recycling composite materials. Up to now, composite materials used on airplanes are something relatively new, and most of planes recycled today are made of metals. Those are very easy to recycle, because they can me melted and reshaped. Composite materials are very different to that regard, and we still don’t know how to recycle them.

Composite materials like carbon fiber are very difficult to recycle because composed of two different materials “glued” together, that are hardly separated.

All of these are important issues that are important, but go most of the time unnoticed or unspoken of. But we are going to have to come up with one or multiple solutions for this growing issue, if we don’t want to end up with graveyards growing bigger each year.